The Label Line offers an in-line finishing solution from strips, carrying out a pre-cut, final cut and banding of the items. A high degree of accuracy is achieved by using counter-pressure punching as standard.

Use

Designed for high volume production of labels, but can be used equally effectively for the production of telephone cards – and other shapes – in paper, board or plastic/PVC.

Cost savings

Cost savings

Significant cost savings can be achieved because of the patented method of inter-locking labels; the savings are both in material and production costs since interlocking allows more labels to be laid down on each sheet – savings of 35% of material costs are typical.

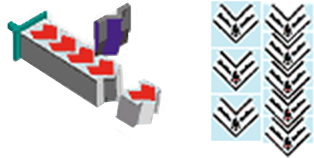

Label production line in action

In-line production of neck labels for champagne bottles

How it works

- The Label Line takes cut strips which are fed automatically into the first element of the Label Line for the pre-cut, this is the Strip Punch,

- The Strip Punch is where the labels (or phonecards) are separated by a vertical punch;

- Each pile is then moved forward into the counter-pressure unit where the final cut is made

- The finished pile is banded and moved into the delivery.

Non-stop feeding

This is possible from the guillotine, and normally the guillotine operator controls the speed of operation. Only one other staff member is needed, to pack the finished items or move them on to the next process (i.e. shrink wrapping).

The Strip Punch

The Strip Punch is the first element of the Label Line.

It is also available separately for the pre-cutting of labels (or other products) which are then ram-punched (manually) to the finished shape. This still allows interlocking and so material saving. The strips are fed automatically into the strip punch where the vertical punch separates the individual piles. These are then removed manually for the next process.

Configuration example: of strip puncher, punching machine and table banding machine